Amazon Sustainability Accelerator Video features HTMS

Amazon has produced a promotional video for its Sustainability Accelerator program featuring our CEO Tom Grizzetti:

HTMS Wins Heating & Ventilation News 2025 Award

H&V News Awards 2025 celebrated excellence across the heating, ventilation and air conditioning industry

01 December 2025

The 2025 H&V News Awards, the flagship event recognising the outstanding achievements of the HVAC sector, revealed its winners last night at a prestigious ceremony attended by industry leaders, innovators, and rising stars from across the sector.

Held in front of a packed audience, the awards honoured the organisations, projects, and individuals driving net zero progress and technical excellence across the built environment.

This year’s diverse range of finalists represented the very best businesses and professionals, who have demonstrated their commitment to shaping a safer, more efficient, and more environmentally responsible industry. From pioneering decarbonisation initiatives to groundbreaking product development and exceptional customer service, the 2025 winners exemplify the innovation and dedication transforming the sector.

HT Materials Science was awarded Commercial HVAC Product of the Year – Cooling Technology, with the H&V News Awards Judging Panel 2025 praising Maxwell for “its mature technology refined to new heights of performance, demonstrating thoughtful design and adaptability to market needs”.

Speaking at the ceremony, H&V News editor, Ella Mackenzie said:

“It was an honour to host these awards for the first time, and see the diverse range of talented professionals and incredible projects being undertaken across every corner of the UK, from small residential installations to huge industrial retrofits.

Thank you to everyone who took the time to share their work with us this year, both through their awards entries and through articles and case studies featured in the magazine. It’s been a pleasure to hear from you all, and I look forward to seeing what you accomplish in 2026”.

Reproduced from the original article

HTMS Secures €2.3m in DTIF Funding

A DCU consortium led by HT Materials Science Ltd (HTMS) has secured €2.3m in funding from the Disruptive Technologies Innovation Fund (DTIF) in Ireland

02 October 2025

The project, DLCool, is a collaboration between three partners, two based at DCU:Innovate Hub, HTMS and Exergyn Ltd, and DCU. The DCU academic leads are Dr Lorna Fitzsimons (School of Mechanical and Manufacturing Engineering) and Dr Darren Fayne (School of Chemical Sciences). DLCool was the only project to receive an award in the “manufacturing & materials” category of this call.

A defining strength of this collaboration is the close and growing integration between DCU researchers and innovation-driven companies based at DCU:Innovate Hub.

Denis Kearney, General Manager (Ireland), HT Materials Science Ltd, commented:

"We are delighted that our project has been approved under DTIF-7. This €3.7 million initiative, supported with €2.3million in grant aid, represents a major step forward in developing novel thermally conductive nanofluid additives for next-generation cooling solutions. As project lead, HTMS will drive innovation in direct liquid cooling for data centres, solid state heat pumps, and electric batteries - three critical sectors for Europe's energy transition. This award not only recognises the potential of our technology but also underlines Ireland's role in pioneering advanced materials to deliver both sustainability and performance at scale."

Kevin O’Toole, Co-Founder and CTO, Exergyn, added:

"This project brings together leading academic expertise and industrial know-how. We're excited to advance thermal management technologies, strengthen Ireland's manufacturing base, and open new commercial opportunities for our solid-state platform."

With this funding, DCU further consolidates its reputation as a research and innovation partner to industry, bridging AI, advanced manufacturing and thermal systems to industrial applications.

Commenting on this, Prof John Doyle, Vice-President for Research at Dublin City University, stated:

"DLCool exemplifies the power of collaboration between academia and industry and the importance of location on a university Innovation campus such as DCU:Innovate Hub. By combining DCU’s research excellence with the innovation capacity of our partners, this project has the potential to transform sustainable cooling technologies and deliver real impact for Ireland and beyond.”

Fast Company Award for 2025

HTMS selected by Fast Company as one of 10 most innovative companies in manufacturing for 2025

March 18th, 2025

Rob Pegoraro

Advances in manufacturing (faster, cheaper, smarter) don’t always result from one big technological breakthrough: much of the work of innovation involves building on what people have accomplished before.

Both P2 Science and HT Materials Science have drawn on their own inventions in chemistry to create cleaner and greener cosmetics and to make heating and air-conditioning systems more efficient and less thirsty for water. And since HT counts factories among its clients, future occupants of this list may rank among the beneficiaries of its work.

5. HT Materials Science

For identifying an additive that makes HVAC systems more efficient

The digital revolution giveth, and the digital revolution taketh away: On the one hand, smart technologies are improving energy efficiency; on the other, data centers and crypto-mining operations and fulfilment operations consume a massive and growing amount of energy that’s expected to double by 2030. About 40% of that consumption is attributable to energy required to keep operations cool.

Dublin-based startup HT Materials Science doesn’t make heating/ventilation/air-conditioning systems, but it does make the HVAC hardware already installed at commercial and industrial sites significantly more efficient. The company accomplishes this with its proprietary drop-in additive called Maxwell, which suspends microscopic particles of aluminum oxide in water or a mixture of water and glycol to improve heat transfer. Adding just a tiny bit to an HVAC system’s water or water-glycol mix helps juice efficiency by up to 20%.

HTMS has strategic partnerships with a number of prominent companies, including Regeneron and Saudi Aramco, and in May 2024 it was accepted into Amazon’s Sustainability Accelerator to deploy Maxwell at a trio of fulfilment centers in the U.K.

‑ Reproduced from original source

Forbes Council Article

How Commercial Building Owners Can Leverage Cost-Effective Retrofitting

Dec 23, 2024,07:45am EST

Thomas Grizzetti, CEO, HT Materials Science

As we prepare to leave 2024 behind and look ahead to 2025, it’s important to recognize how far the commercial HVAC industry has come—especially as businesses across the world continue seeking our help in reducing operating costs, carbon emissions and, of course, energy bills. It’s also important to think about what more we can be doing—and about just how impactful and far-reaching HVAC efficiency improvements can be when implemented at scale.

Companies are adopting greener, more energy-efficient systems. Energy efficiency standards, like those set by ASHRAE, are crucial drivers. These evolving standards are forcing companies to rethink their energy strategies. Local laws, such as New York’s Local Law 97, are further driving the need for more aggressive energy-efficiency measures, ensuring that cities continue progressing toward their decarbonization goals.

I haven’t always been passionate about the HVAC industry, but after several decades of investing in companies across a variety of sectors, I began to fully grasp the HVAC industry’s need for both innovation and reduced environmental impact. Now, as CEO of a company providing simple retrofit solutions for commercial HVAC systems, I recognize that upgrading HVAC equipment or replacing it entirely is not feasible for most companies. The path to a more sustainable HVAC future doesn’t have to rely solely on capital expenditures. Instead, businesses can explore lower-cost innovations, retrofits and optimizations to existing systems to reduce energy consumption and improve cost-efficiency.

Sustainability Isn’t Just About New Equipment

Sustainability shouldn’t come with a blanket prescription to “buy new.” In my experience, smart retrofitting can yield immediate benefits, including reduced energy consumption, without the high costs and operational disruptions of replacing entire systems.

For example, instead of replacing an entire HVAC system, companies can install more efficient compressors, variable-speed pumps or upgraded controls to maximize performance.

Retrofitting also has the added benefit of extending the lifespan of current systems, giving building owners more time before they need to consider a costly replacement. And, perhaps most importantly, retrofits involve less disruption to daily operations compared to full equipment replacement.

The Double-Edged Sword Of New Refrigerants

One area where the HVAC industry is seeing mandated change is refrigerants. For years, traditional refrigerants like R-410A have been used in HVAC systems. However, these refrigerants are being phased out due to environmental regulations aimed at protecting the ozone layer. The next wave of refrigerants is less harmful to the environment in terms of emissions, but they often come with a trade-off: lower efficiency.

Refrigerants play a critical role in heat transfer, and as newer, more environmentally friendly options are introduced, I believe the efficiency of HVAC systems will likely decrease. This change may be problematic for businesses trying to reduce their carbon footprint and control energy expenses. That said, a well-planned retrofit can maintain or increase system efficiencies and avoid skyrocketing energy costs.

Understanding Efficiency And The Grid

One of the hidden advantages of making HVAC systems more efficient is the relief it provides to the power grid. Energy-efficient systems consume less electricity, helping reduce strain on local power supplies. This reduced consumption can help prevent rolling brownouts or blackouts, which are increasingly common as the demand for energy-intensive services, such as data centers, grows. Retrofitting commercial buildings with more efficient HVAC systems can benefit both building owners and tenants by reducing electricity demand (especially during peak periods) and operating costs over time while keeping building temperatures comfortable.

District Energy: An Overlooked Champion

One area where significant sustainability gains are being made is district energy systems. These systems allow for the sharing of heating and cooling resources among multiple buildings or even cities, making them significantly more efficient than standalone HVAC systems. District energy systems can capture waste heat from one building—such as a data center—and use it to provide heating to other buildings nearby. This energy recovery can create a circular energy economy, reducing the need for additional energy production.

Preparing Your Building For A Retrofit

In order to understand and prepare for a retrofit, building owners must first understand whether the technology is suitable for their buildings. To start, building owners should review the past performance of the proposed retrofit, review the installation and maintenance procedures for potential disruption to operations, and, of course, have a keen understanding of the economics of the retrofit investment (i.e., ROI & payback), including any product warranties and performance guarantees.

Initially, building owners should focus on performance verification. This process starts with the review of energy efficiency data provided by the retrofit vendor for a building with similar size, construction type and cooling/heating loads as well as comparable HVAC equipment and seasonal operating metrics. Secondly, request and review any third-party performance certifications.

If you are satisfied that the data provided is acceptable, then the building owner must request and approve a measurement and verification (M&V) plan from the retrofit vendor. The M&V plan should include a protocol to compare the baseline operating metrics of the building before the installation of the retrofit to the new operating metrics of the building after the installation of the retrofit technologies. A generally accepted M&V protocol is the International Performance Measurement and Verification Protocol (IPMVP). Most M&V plans should run for 12 months with monthly reporting and periodic reporting thereafter.

Next, I would recommend a deep read into the installation and maintenance procedures. Generally, there should never be a material disruption to the operations of your building, and the existing building control system should be able to monitor, control and optimize the retrofit. Finally, owners should take steps to understand the economics. What are the annual energy savings versus retrofit cost (i.e. payback)? How does the payback compare to the ROI (i.e., useful life of retrofit/payback)?

These preparation procedures may seem daunting, but with proper due diligence, building managers in coordination with HVAC service will be able to make an informed decision.

The Future: Smarter, More Flexible Systems

The HVAC industry is nearing a plateau in squeezing more efficiency from traditional chiller and heat pump equipment. The next generation of technology must be smarter (e.g., AI-based system and building optimization strategies) and more adaptable. Building owners and operators should consider implementing a blend of retrofitting, improved controls and leveraging new technologies, as well as prioritizing solutions to deliver both short-term gains and long-term sustainability.

Ecovadis Bronze Medal for Sustainability

World-recognized organisation assesses the sustainability performance of companies

DUBLIN, Oct. 22, 2024

HT Materials Science recently applied for the EcoVadis global sustainability rating. We are proud to announce that we have been awarded the Bronze Medal in our first-ever rating.

EcoVadis is a world-recognized organisation which assesses the sustainability performance of companies by evaluating the environmental, social and ethical aspects of their operations.

Achieving the Bronze Medal demonstrates the HTMS commitment to sustainability and responsible business practices. It reflects the dedication and hard work of our employees in integrating sustainable principles and practices into our daily operations.

Our participation in the Ecovadis platform and network provides HTMS with valuable feedback and support in continuing to improve our ratings in each of the key evaluation categories, enhancing our company-wide efforts toward outstanding corporate sustainability.

Maxwell at Amazon UK Fulfilment Centers

HT Materials Science Selected by Amazon to Pilot Energy-Efficient Nanofluid Technology

DUBLIN, Oct. 21, 2024 /PRNewswire/

HT Materials Science (HTMS), a pioneering green tech company specializing in energy-efficient solutions, has been selected as one of eleven sustainability-focused start-ups that will trial their technology with Amazon across Europe after receiving funding in this year’s Amazon Sustainability Accelerator. HTMS will pilot its cutting-edge Maxwell™ nanofluid technology across three Amazon fulfilment centers in the UK—Coventry, Daventry, and Doncaster.

HTMS’ innovative solution is designed to improve the performance of heating, ventilation, and air conditioning systems (HVAC) by enhancing heat transfer efficiency. Maxwell™, which has already garnered international recognition, including the prestigious Green Product Award, is expected to reduce energy consumption in some of Amazon’s UK HVAC systems by up to 14%.

“We are thrilled to be piloting our technology with Amazon as part of this year’s Amazon Sustainability Accelerator,” said Ben Taylor, Vice President of HT Materials Science. “Maxwell™ has the potential to deliver significant energy savings and reduce the associated carbon emissions across the fulfilment centers. By improving the energy efficiency of these HVAC systems, we are supporting Amazon’s sustainability commitments and demonstrating the real-world impact of our technology.”

The pilot will kick off in 2024, with the technology being integrated into Amazon’s heating and cooling systems at key fulfilment centers. HTMS’ nanofluid solution has been designed to increase thermal conductivity, enabling HVAC systems to operate more efficiently without requiring additional energy inputs. The result is a reduction in energy use, lower operational costs and a significant decrease in carbon emissions.

A Potential Long-Term Partnership

Throughout the pilot, HTMS will work closely with Amazon’s subject matter experts and seek opportunities to refine its technology to ensure a successful implementation. Upon completion, the environmental impact, financial viability and overall effectiveness will be assessed to determine whether it can be scaled across other HVAC systems at Amazon sites as part of a long-term partnership.

HTMS is one of eleven start-ups from across Europe (as well as the US and Canada) that have been awarded the opportunity to test their innovations with Amazon operations.

About Amazon Sustainability Accelerator

Since its launch in 2022, the Amazon Sustainability Accelerator has supported over 40 start-ups across Europe and the UK. The initiative provides funding, mentorship, and the opportunity for start-ups to pilot their technologies within Amazon’s operations, with the goal of driving sustainable innovation and reducing the company’s environmental impact.

International EPD System Database lists Maxwell

HTMS are pleased to announce that after extensive due diligence by third-party environmental product specialists, Maxwell’s Life Cycle Analysis (LCA) has been approved and accepted by the International EPD System for listing on their database and website.

The full declaration is available here: https://www.environdec.com/library/epd11974

For most installations of Maxwell in Chilled Water Systems, the CO2 breakeven is less than one year on CO2 emissions saved, compared to the emissions generated during manufacturing and use of Maxwell, as shown in the LCA calculations. In many cases, the breakeven is just a few months.

The LCA assesses environmental impacts associated with all stages in the life cycle of a commercial product, process, or service. including materials procurement, production, shipping, installation, and End of Life (EOL). Maxwell is fully recoverable from the system fluid, and recyclable.

‑ Reproduced from original source

Maxwell Wins 2024 Green Product Award

HT Materials Science’s Pioneering Heat Transfer Fluid, Maxwell™,

Wins 2024 Green Product Award

May 1, 2024 (Dublin, IRELAND) – HT Materials Science (HTMS), the sustainable materials technology company based in Ireland with operations in Italy and the USA, was awarded the Green Product Award 2024 for their proprietary heat transfer fluid Maxwell™. A record of 1,500 applicants from 60 countries applied for the Awards, demonstrating the growing importance of sustainable products and materials in shaping a more sustainable future. Every year, the Green Product Award recognizes products and concepts that stand out in terms of design, innovation and sustainability. The winners in 12 categories have now been selected from 250 nominated products and concepts.

Maxwell won the Green Product Award 2024 in the Building Components category during the awards ceremony held on April 30th at the Nordic Embassies in Berlin. Embassy envoys and jurors such as Katarzyna Dulko-Gaszyna (IKEA Germany), Uwe Melichar (epda), Prof. Claus-Christian Eckhardt (Lund University), Katja Keienburg (baby&junior) presented the awards to winners from Austria, Belgium, Brazil, Canada, Denmark, Finland, Germany, Ireland, Israel, Italy, Netherlands, Nicaragua, Poland, Portugal, Spain, Sweden, Switzerland, Taiwan and the United Kingdom.

“Commercial and industrial cooling and heating applications in particular require a lot of energy and therefore cause considerable CO2 emissions. This innovative solution in the form of a heat transfer fluid can be retrofitted to existing systems, saves costs and demonstrably reduces energy consumption.” Official Jury Statement

Maxwell is an innovative heat transfer fluid additive that provides higher thermal capacity for water or water-glycol based HVAC systems. Improved fluid properties in cooling or heating systems are key to reducing energy use. HT Materials Science is in the vanguard to deliver the promise of nanofluid additives with the release of Maxwell.

About HTMS

HTMS is the producer of Maxwell – a patented drop-in heat transfer fluid additive for water based commercial and industrial HVAC systems. Maxwell increases the thermal energy transfer of HVAC systems, resulting in a substantial reduction in energy consumption and/or an increase in its thermal capacity. The company is headquartered in Ireland with offices in Italy, New York and Dubai. For more information visit www.htmaterialsscience.com

About the Green Product Award

Since 2013, the international Green Product Award has been honoring products and services that stand out in terms of design, innovation and sustainability. In cooperation with the IKEA Stiftung, the Green Concept Award evaluates concepts by young designers and supports their further development.

Media Contact:

htms@misfittoyscomms.com

‑ Reproduced from original source

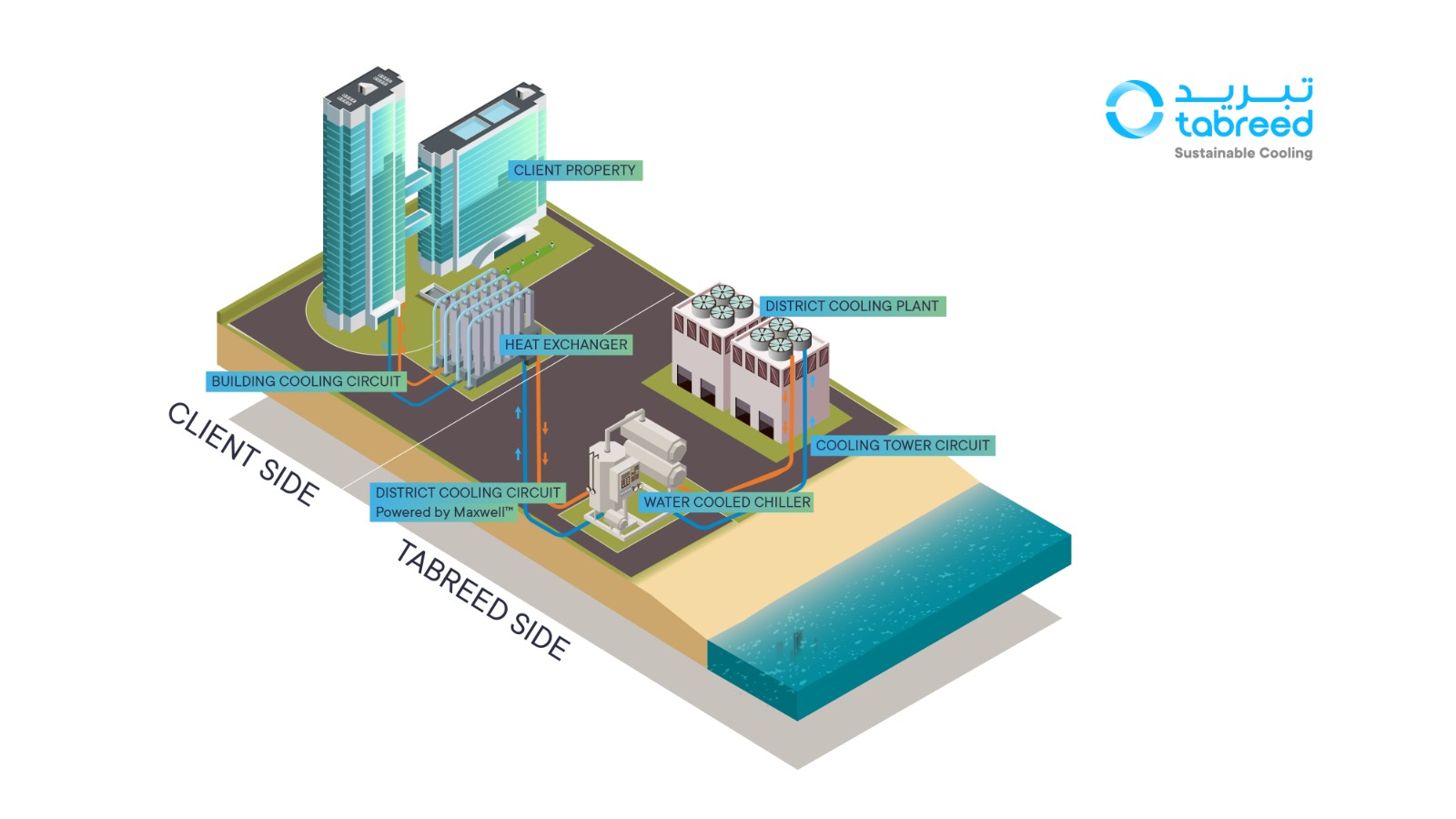

Tabreed Boosts its Roadmap to Net-Zero

Tabreed Boosts its Roadmap to Net-Zero, following Impressive Results from World-first District Cooling Nanofluid Pilot Study

Thursday, November 09, 2023

Pioneering nanofluid technology, developed by HTMS, demonstrates potential to increase District Cooling energy efficiency by up to 15%

Abu Dhabi, United Arab Emirates – 09 November 2023: Tabreed, the world’s leading district cooling company, in partnership with Ireland-based HT Materials Science (HTMS), has concluded what is believed to be the world’s first pilot project of its kind, demonstrating results that provide real hope for significant gains in energy efficiency.

Applied across Tabreed’s current portfolio of 89 district cooling plants, the heat transfer fluid technology developed by HTMS – known as ‘Maxwell’ – could result in efficiency increases of between nine- and 15%. Theoretically this could mean preventing approximately 200,000 metric tons of greenhouse gas (GHG) emissions annually, as a result of decreased electrical energy consumption. For context, this would equate to removing 43,500 cars from the roads each year as a result of saving 335 million kWh of electricity, which is enough to power approximately 20,000 homes.

Maxwell, named after James Clerk Maxwell, the pioneering scientist who first developed the concept of nano fluids in the 19th century, is an engineered suspension of sub-micron aluminium oxide particles in a base fluid of water or water/glycol (‘nanofluid’) – a drop-in additive for cooling and heating systems, that works by enhancing heat transfer. It was trialled in the summer of 2023 at a Tabreed district cooling plant in Khalifah City, Abu Dhabi, which exclusively supplies chilled water to a 55,742 square metre educational campus.

The performance of the Maxwell nanoparticle fluid technology at Tabreed’s facility, evaluated under industry-approved Energy Efficiency Analysis (EEA), demonstrated that its addition increased efficiency of the plant’s chillers by 13.6%, leading to an overall plant efficiency improvement of 9.0%, compared with the same period in 2022.

Tabreed’s CEO, Khalid Al Marzooqi, said this development is testament to the company’s tireless pursuit of energy efficiency at every level of its operations, adding that “as a sustainable cooling champion focused on innovation, we are always looking for ways to accelerate the energy transition and provide more efficient services that benefit our customers, our stakeholders and the communities in which Tabreed operates.

“This successful pilot project proves the power of international partnership and technological collaboration, and we look forward to working with HTMS to further the application of their technology to advance sustainable cooling solutions that benefit communities and industries across the world.

“In real terms, what we are looking at here is a potentially seismic improvement in energy efficiency that could radically change this industry. That Tabreed is spearheading such developments should not be a surprise, and I am proud to be leading such a progressive and impactful company that’s completely aligned with the UAE’s inspirational Net-Zero strategy.”

How Maxwell Works in a Chilled Water System

Maxwell’s nanotechnology increases the thermal capacity of water, the base fluid for commercial and industrial chilled water systems. When added to a chilled water loop at a 2% concentration of nano materials, Maxwell increases the system’s cooling capacity by up to 15%. This increased cooling capacity allows chillers, fan units, pumps and other equipment to operate more efficiently, reducing electrical energy consumption and carbon emissions. Maxwell is a non-toxic, non-corrosive material and fully recoverable and recyclable.

Next Steps

Following the promising pilot study results, Tabreed and HTMS are in discussions to introduce the Maxwell technology to other district cooling facilities in the company’s portfolio. With cooling accounting for an estimated 70% of energy consumption in the GCC, and global demand expected to triple by 2050, this technology could potentially play a critical role in reducing the environmental impact of an industry already widely viewed as an essential contributor to sustainability, with district cooling being up to 50% more energy efficient than conventional cooling methods.

Commenting on the successful pilot project, Thomas Grizzetti, CEO of HTMS, said: “Thanks to the ease of installation, and use in both new and existing HVAC systems, Maxwell can have a material impact on energy usage and the carbon footprint of a broad range of industries and sectors globally. Maxwell is a significant step forward for businesses wishing to drive down energy use, increase system capacity and meet regulated energy efficiency targets increasingly promulgated by governments globally. We believe Tabreed is an ideal strategic partner for HTMS to help achieve widespread adoption of this unique technology.

‑ Reproduced from original source