Tabreed Boosts its Roadmap to Net-Zero

Tabreed Boosts its Roadmap to Net-Zero, following Impressive Results from World-first District Cooling Nanofluid Pilot Study

Thursday, November 09, 2023

Pioneering nanofluid technology, developed by HTMS, demonstrates potential to increase District Cooling energy efficiency by up to 15%

Abu Dhabi, United Arab Emirates – 09 November 2023: Tabreed, the world’s leading district cooling company, in partnership with Ireland-based HT Materials Science (HTMS), has concluded what is believed to be the world’s first pilot project of its kind, demonstrating results that provide real hope for significant gains in energy efficiency.

Applied across Tabreed’s current portfolio of 89 district cooling plants, the heat transfer fluid technology developed by HTMS – known as ‘Maxwell’ – could result in efficiency increases of between nine- and 15%. Theoretically this could mean preventing approximately 200,000 metric tons of greenhouse gas (GHG) emissions annually, as a result of decreased electrical energy consumption. For context, this would equate to removing 43,500 cars from the roads each year as a result of saving 335 million kWh of electricity, which is enough to power approximately 20,000 homes.

Maxwell, named after James Clerk Maxwell, the pioneering scientist who first developed the concept of nano fluids in the 19th century, is an engineered suspension of sub-micron aluminium oxide particles in a base fluid of water or water/glycol (‘nanofluid’) – a drop-in additive for cooling and heating systems, that works by enhancing heat transfer. It was trialled in the summer of 2023 at a Tabreed district cooling plant in Khalifah City, Abu Dhabi, which exclusively supplies chilled water to a 55,742 square metre educational campus.

The performance of the Maxwell nanoparticle fluid technology at Tabreed’s facility, evaluated under industry-approved Energy Efficiency Analysis (EEA), demonstrated that its addition increased efficiency of the plant’s chillers by 13.6%, leading to an overall plant efficiency improvement of 9.0%, compared with the same period in 2022.

Tabreed’s CEO, Khalid Al Marzooqi, said this development is testament to the company’s tireless pursuit of energy efficiency at every level of its operations, adding that “as a sustainable cooling champion focused on innovation, we are always looking for ways to accelerate the energy transition and provide more efficient services that benefit our customers, our stakeholders and the communities in which Tabreed operates.

“This successful pilot project proves the power of international partnership and technological collaboration, and we look forward to working with HTMS to further the application of their technology to advance sustainable cooling solutions that benefit communities and industries across the world.

“In real terms, what we are looking at here is a potentially seismic improvement in energy efficiency that could radically change this industry. That Tabreed is spearheading such developments should not be a surprise, and I am proud to be leading such a progressive and impactful company that’s completely aligned with the UAE’s inspirational Net-Zero strategy.”

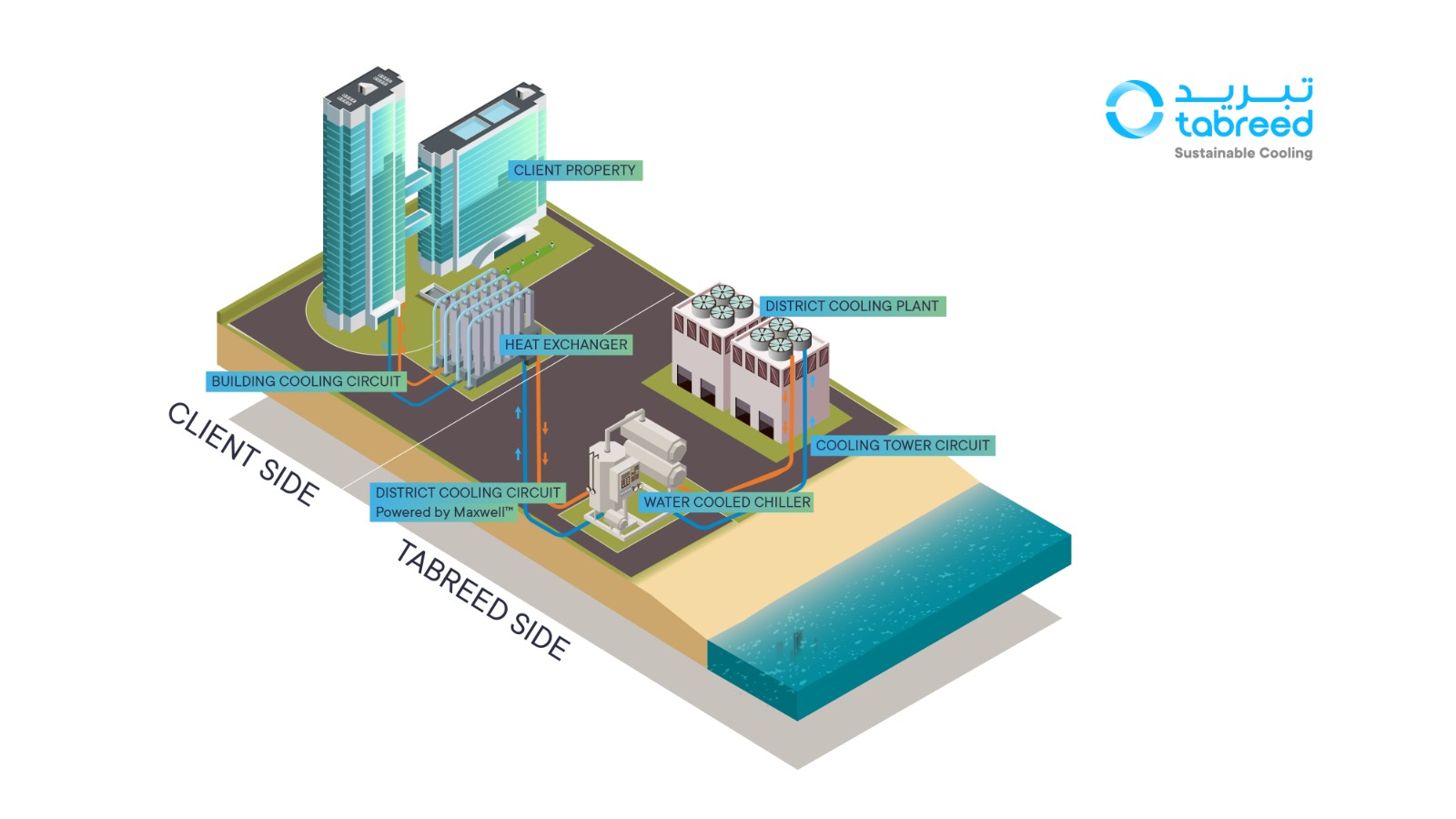

How Maxwell Works in a Chilled Water System

Maxwell’s nanotechnology increases the thermal capacity of water, the base fluid for commercial and industrial chilled water systems. When added to a chilled water loop at a 2% concentration of nano materials, Maxwell increases the system’s cooling capacity by up to 15%. This increased cooling capacity allows chillers, fan units, pumps and other equipment to operate more efficiently, reducing electrical energy consumption and carbon emissions. Maxwell is a non-toxic, non-corrosive material and fully recoverable and recyclable.

Next Steps

Following the promising pilot study results, Tabreed and HTMS are in discussions to introduce the Maxwell technology to other district cooling facilities in the company’s portfolio. With cooling accounting for an estimated 70% of energy consumption in the GCC, and global demand expected to triple by 2050, this technology could potentially play a critical role in reducing the environmental impact of an industry already widely viewed as an essential contributor to sustainability, with district cooling being up to 50% more energy efficient than conventional cooling methods.

Commenting on the successful pilot project, Thomas Grizzetti, CEO of HTMS, said: “Thanks to the ease of installation, and use in both new and existing HVAC systems, Maxwell can have a material impact on energy usage and the carbon footprint of a broad range of industries and sectors globally. Maxwell is a significant step forward for businesses wishing to drive down energy use, increase system capacity and meet regulated energy efficiency targets increasingly promulgated by governments globally. We believe Tabreed is an ideal strategic partner for HTMS to help achieve widespread adoption of this unique technology.

‑ Reproduced from original source