Building the future: Sustainable practices for efficient and affordable housing

Sustainability considerations now permeate the entire property value chain

CONSTRUCTION WEEK (Middle East) – by Medea Nocentini July 09, 2024

With growing sustainability concerns and heightened scrutiny over various sectors’ contributions to climate change, the property sector’s impact is under the spotlight. As the largest asset class globally, with a market size exceeding $338 trillion in 2022, the property sector’s status quo is being re-evaluated through the lens of sustainability.

Sustainability considerations now permeate the entire property value chain, affecting designers, developers, property managers, regulators, residents, and tenants. Currently, 43% of global carbon dioxide (CO2) emissions stem from the real estate sector, with building operations accounting for approximately 70% and construction contributing the remaining 30%.

Investors are increasingly prioritising sustainable practices, recognising both the potential value and profitability in properties managed with a focus on sustainability. Among these investors, 63% are exploring the adoption of building and IoT sensors, while 62% are investigating automated energy management as well as sustainability monitoring and reporting.

Innovative approaches to sustainability in the property sector

The sustainability shift within the property sector is compelling, driven by cutting-edge solutions in material sciences, 3D printing, water management and energy efficiency. As the third-largest contributor to CO2 emissions, the potential for a net-zero paradigm shift in property development is significant, promising climate-conscious developments that enhance efficiency and affordability.

Beyond material choices, there is a clear move towards sustainability in building amenities and central HVAC systems. Lighting and other energy-efficient systems are being integrated from the early stages of the value chain.

Initiatives like the UAE’s Al Sa’fat and Pearl rating systems, Saudi Arabia’s evolving national building codes, and the Africa Green Building Finance Initiative emphasise the need to incorporate sustainability into decision-making processes.

On the water management side, Ireland’s HT Materials Science, with Saudi Aramco as one of their clients in the GCC region, develops advanced heat transfer fluids, focusing on enhancing the efficiency of cooling and heating systems.

Their primary product, Maxwell™, is a nanofluid additive that improves thermal performance by up to 15%, leading to lower energy consumption and reduced carbon emissions.

Maxwell™ can be integrated into existing systems without significant modifications, making it suitable for a range of applications including commercial buildings and data centers.

The shift towards sustainability in the property sector is not just a response to environmental concerns but a comprehensive strategy to enhance efficiency, profitability, and affordability.

By embracing innovative materials, advanced manufacturing techniques, and energy-efficient practices, the property sector can significantly reduce its carbon footprint while meeting the growing demand for sustainable and affordable living spaces.

‑ Reproduced from original source

"This new heat transfer fluid can take 15% off your energy bill"

Calling all real estate managers, factory operators, hospitals and data centers: This new heat transfer fluid can take 15% off your energy bill

![]()

Posted on June 28, 2024 by Karin Kloosterman in Green Tech and Gadgets, Technology

Dublin based HT Materials Science (HTMS) has developed a breakthrough energy savings solution called Maxwell that can slash operating costs, increase system capacity in new and existing builds and offer carbon credits.

Water is the universal heat transfer fluid for commercial and industrial HVAC systems. While water is plentiful and cheap there are additives to water which can improve its thermal capacity and that’s the elegant and planet-smart idea from Irish-Italian company HT Materials Science based in Dublin, Ireland.

HTMS has developed a heat transfer fluid branded Maxwell to increase the thermal capacity of water –– allowing it to store up to 20% more energy than water alone. At only a 2% additive to water, Maxwell can provide up to a 20% increase in performance and reduce greenhouse gas emissions in no small way.

HT Materials Science was founded in 2018 to develop a heat transfer fluid for commercial and industrial HVAC markets. Among its investors are Saudi Aramco Energy Ventures, which led a €15M Series A round in 2021, and Barclays Bank, via its Sustainable Impact Capital portfolio.

HT Materials Science CEO Tom Grizzetti tells Green Prophet: “There has certainly been development activity in heat transfer fluids over the last decade-plus. However, the combination of product stability, proven performance and client engagement has been elusive.

“With Maxwell, a multi-patented product, we bring to market a solution that was developed to satisfy both the science and the business sides of the equation. These efforts have resulted in a stable product with provable performance and ultimately significant client engagement,” he adds.

Maxwell is an engineered suspension of sub-micron aluminum oxide particles in a base fluid of water or water/glycol (that last part is significant since it means Maxwell can be used in systems that use either water or glycol as their base fluid)—resulting in reduced energy use, emissions, maintenance and costs; and an increase in system capacity.

Same temperature, less energy

Consider that heating and cooling are attributed to almost half of our planet’s energy consumption, and about 40% of carbon dioxide and equivalent carbon emissions.

Among HT Material Science’s first industrial clients is the German based alumina producer Almatis. By installing Maxwell into the plant’s cooling system, HTMS increased the system capacity by up to 20% while increasing operational output.

HT Materials Science is on a mission looking to expand throughout the Middle East as countries like the UAE and Saudi Arabia develop manufacturing and technology parks to keep production facilities like electric cars close to home.

Maxwell is a pretty neat fluid that will be a game changer for carbon accounting globally.

‑ Reproduced from original source

Dublin-based Energy Start-Up Joins Amazon’s Green Scheme

Dublin-based start-up HT Materials Science has joined the Amazon Sustainability Accelerator, aiming to expand its retrofit solution for heating and cooling systems

Dimitris Mavrokefalidis

Energy Live News

05/29/2024 10:30 AM

Dublin‘s HT Materials Science has been selected to participate in the Amazon Sustainability Accelerator, joining 15 other European start-ups in the initiative’s third edition. The accelerator offers a four-week programme designed to empower start-ups addressing global sustainability challenges.

HT Materials Science, founded in 2018, has developed a retrofit solution that enhances heating and cooling systems’ efficiency. This technology, named Maxwell heat transfer fluids, can be integrated into existing commercial and industrial systems, delivering significant energy savings of up to 15% while reducing carbon dioxide emissions.

The expanded accelerator programme, a partnership between Amazon, EIT Climate-KIC and Founders Intelligence, aims to support entrepreneurs in scaling their sustainable solutions.

Thomas Grizzetti, Chief Executive Officer of HT Materials Science, said: “Between 1990 and 2020, energy used for cooling tripled and will continue to increase as global economies expand and temperatures rise.”

Zak Watts, Amazon’s International Director of Sustainability said: “The scope of businesses involved means we can support even more entrepreneurs to reach their potential. “Not to mention the one of a kind opportunity to test their technology directly with parts of Amazon’s business.”

Copyright © 2024 Energy Live News Ltd

‑ Reproduced from original source

Boosting HVAC efficiency with new technologies, additives

Nanofluids offer quick, low-cost ways to improve performance without system upgrades or replacements, manufacturers say, with even newer innovations on the horizon.

March 14, 2024 (Facilities Dive News, Joe Burns reporting) –

Space heating, cooling and ventilation represent more than half of the total fuel consumption in the U.S. commercial sector. Among these, space heating is the largest segment, at 32%, followed by ventilation at 11% and cooling at 9%, according to the U.S. Energy Information Administration.

In part due to HVAC systems’ large energy demands, these systems require careful consideration in maintenance, operating and capital expenditure budgets. They often require more maintenance attention — and use more energy — as they age due to issues like dirty coils, corrosion in refrigerant loops and heat exchanger oil fouling. The latter problem can lead to efficiency losses, maintenance costs resulting from the removal of fouling deposits or the replacement of corroded or plugged equipment. More concerning, perhaps, is that oil fouling can require planned or unplanned system shutdowns, according to research by Hassan Al-Haj Ibrahim of the Arab University for Science and Technology. To improve the life cycle of heating and cooling systems, reduce oil fouling problems and improve efficiency, some building operators are looking to new chemical and material science technology additives like nanofluids.

Certain additives have the potential to significantly improve HVAC output. Research in Energy Reports found that using aluminum oxide nanofluid can enhance heat transfer and improve air conditioner system performance by approximately 22%. Because such additives are implemented through noninvasive treatments, they could offer building operators a cost-effective alternative to replacing existing HVAC systems or implementing building automation systems to improve performance.

Where U.S. buildings are using HVAC nanofluids

HT Materials Science offers an aluminum oxide nanofluid product named Maxwell for commercial and industrial thermal systems. The nanoparticles “are only 2% by volume of a typical system, so it’s not a dump and replace. It’s a pure additive, and, generally speaking, no [capital expenditure] is required,” HT Materials Science CEO Tom Grizzetti said in an interview.

The company projects a 10% to 15% increase in energy efficiency across the additive’s more than 10 year life cycle, with those improvements degrading less than 1% in that time, Grizzetti said. HTMS focuses on a two- to four-year payback period, depending on utilization, for its customers, he added.

“We’d like to focus on commercial and industrial because you need [high] utilization,” Grizzetti said. “If you don’t use it, you don’t save.” Large-scale office buildings with district cooling or other “larger infrastructure projects” like an airport are among the use cases he suggests.

HTMS’ Maxwell product was evaluated in a summer 2023 pilot at a district cooling plant in a suburb of Abu Dhabi, United Arab Emirates. The trial, which studied the nanofluid’s effects on chilled water energy use at a 55,742-square-meter educational campus, found that the additive increased the efficiency of the plant’s chillers by 13.6% and increased overall plant efficiency 9% compared with 2022, according to HTMS.

Back in the U.S., HVAC system nanofluids are also being piloted, tested and even celebrated. Phoenix, which expects to exceed last year’s record summer heat this summer, is implementing nanofluid technology to improve cooling systems in city-owned buildings.

Phoenix partnered with ECM Technologies on a $2.5 million contract to implement the company’s ThermaClear nanofluid in HVAC systems of public facilities, with the first phase treating 469 HVAC units across Phoenix fire department and police department buildings. This phase, which concluded in January 2023, treated 3,805 total tons of equipment and is estimated to have provided over 1,350 megawatt hours in annual energy savings to the departments, alongside more than $100,000 saved in annual HVAC service and repair costs, according to the Phoenix Business Journal.

Since then, the partnership has expanded to use the additives in HVAC systems at 16 public library locations, and Sky Harbor International Airport’s treatment is underway. Separately, the Phoenix Art Museum has saved more than $18,000 in annual HVAC energy costs and approximately 123 metric tons of carbon dioxide equivalent since treating its three 350-ton Trane water-cooled chillers with ThermaClear.

“We’re the Lipitor to the HVAC system,” David Fenton, managing director of ECM Technologies, told Facilities Dive, comparing the company’s ThermaClear product to a drug used to reduce “bad” cholesterol and other fats in the bloodstream. “We inject it into the refrigerant loop. It gravitates to the metal and displaces the oil and sludge that’s there, and then it forms a covalent bond to the metal, preventing that oil from sticking.”

In terms of savings, Fenton says the average return on investment for ThermaClear’s one-time treatment is between 12 and 36 months, with operational savings of 15% to 20% per year on average. In addition to cost savings, many companies are implementing ECM Technologies’ nanofluids to drive decarbonization efforts, Fenton noted.

“If we’re reducing electricity [use], we’re definitely having an impact on carbon reduction,” Fenton said. Other goals differ by customer, he said. “Some companies, if we can extend the life of that equipment by another 2, 3 or 4 years and defer [capital expenditures], that’s pretty significant. And then others are looking just to cut their annual operating costs or their biggest fixed cost, which is electricity.”

Other ECM Technologies customers include facilities of Arizona State University, GoDaddy, TransWestern and Morgan Stanley, Fenton said. The firm is focused on serving warmer U.S. regions like the Southwest and Sun Belt. “The most juice for the squeeze in terms of payback, and the fastest performance improvement units, are going to happen in areas where they’re running air conditioning the most,” Fenton said.

Other innovations on the horizon

Material science firms and HVAC firms are starting to work together to improve system efficiency from the outset. For example, Montana Technologies’ AirJoule dehumidification, air conditioning and atmospheric water harvesting technology will incorporate GE Vernova’s proprietary sorbent materials in a new joint venture operating under the AirJoule name, the companies announced Monday.

Researchers at the University of Texas at Dallas are developing a quick-drying polymeric desiccant that could dehumidify buildings using at least 30% less energy than conventional air-conditioning systems.

Shuang Cui, principal investigator and assistant professor of mechanical engineering at the university’s Erik Jonsson School of Engineering and Computer Science, said in a Feb. 21 release that this desiccant material would be used to coat a rotating cylinder, sucking in water and then removing the absorbed moisture as the mechanism rotates and the material is exposed to low heat.

The thermo-responsive material can make air conditioning more efficient by separating the dehumidification and heat removal processes and improving the most energy-consuming processes, the news release said. Unlike traditional air-conditioning systems, those utilizing the new desiccant material would not need to cool coils at low temperatures to condense moisture from the air and would likely not need to be heated to high temperatures to evaporate collected moisture, the release said.

The research is part of an interdisciplinary effort that includes other researchers from Texas A&M University, the University of Utah and private HVAC firm OxiCool. The project, which began in 2023, will continue working to optimize the thermo-responsive polymers to find out which formulas work best at absorbing moisture and drying quickly at low energy input.

‑ Reproduced from original source

Tabreed Boosts its Roadmap to Net-Zero

Tabreed Boosts its Roadmap to Net-Zero, following Impressive Results from World-first District Cooling Nanofluid Pilot Study

Thursday, November 09, 2023

Pioneering nanofluid technology, developed by HTMS, demonstrates potential to increase District Cooling energy efficiency by up to 15%

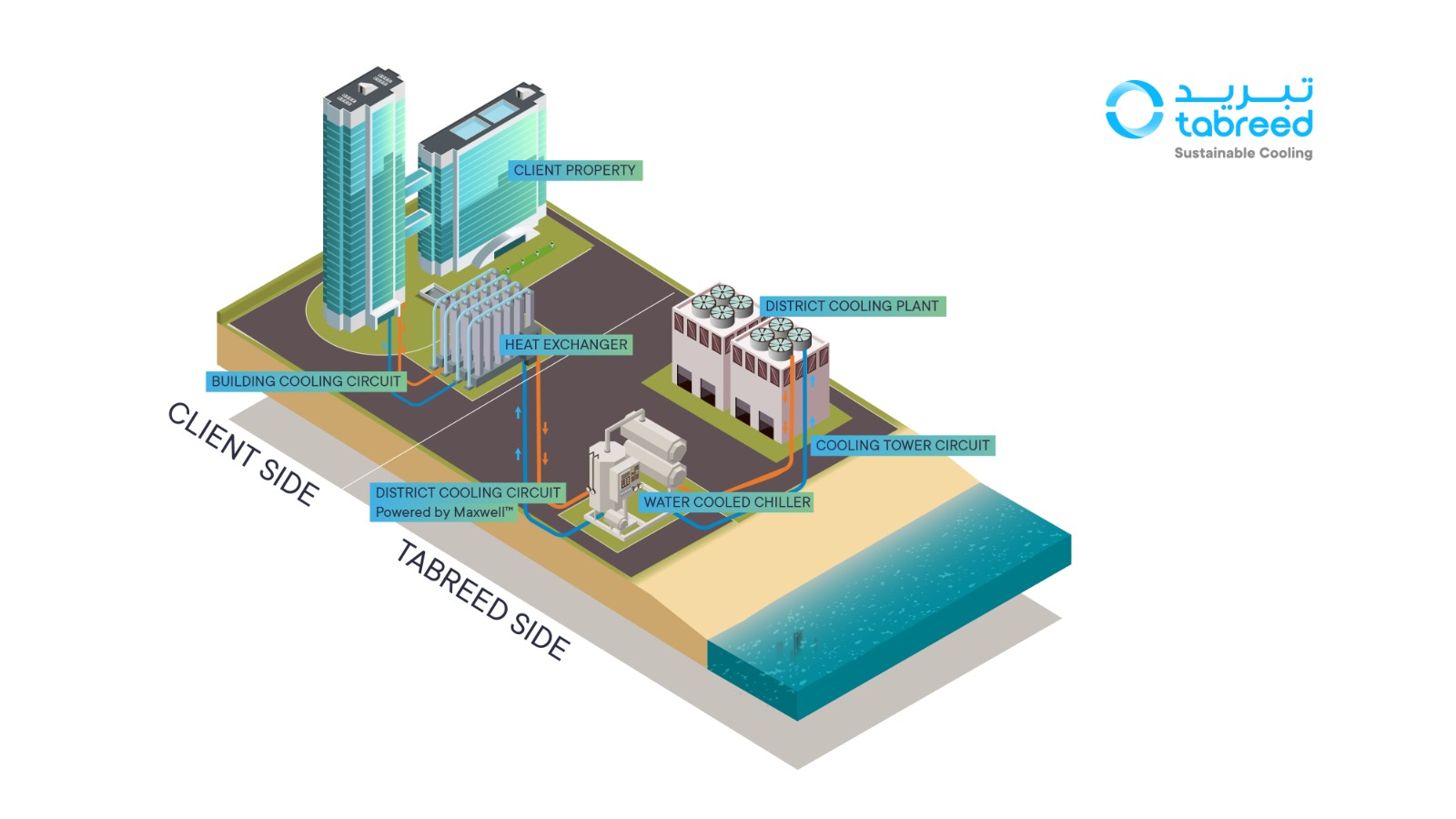

Abu Dhabi, United Arab Emirates – 09 November 2023: Tabreed, the world’s leading district cooling company, in partnership with Ireland-based HT Materials Science (HTMS), has concluded what is believed to be the world’s first pilot project of its kind, demonstrating results that provide real hope for significant gains in energy efficiency.

Applied across Tabreed’s current portfolio of 89 district cooling plants, the heat transfer fluid technology developed by HTMS – known as ‘Maxwell’ – could result in efficiency increases of between nine- and 15%. Theoretically this could mean preventing approximately 200,000 metric tons of greenhouse gas (GHG) emissions annually, as a result of decreased electrical energy consumption. For context, this would equate to removing 43,500 cars from the roads each year as a result of saving 335 million kWh of electricity, which is enough to power approximately 20,000 homes.

Maxwell, named after James Clerk Maxwell, the pioneering scientist who first developed the concept of nano fluids in the 19th century, is an engineered suspension of sub-micron aluminium oxide particles in a base fluid of water or water/glycol (‘nanofluid’) – a drop-in additive for cooling and heating systems, that works by enhancing heat transfer. It was trialled in the summer of 2023 at a Tabreed district cooling plant in Khalifah City, Abu Dhabi, which exclusively supplies chilled water to a 55,742 square metre educational campus.

The performance of the Maxwell nanoparticle fluid technology at Tabreed’s facility, evaluated under industry-approved Energy Efficiency Analysis (EEA), demonstrated that its addition increased efficiency of the plant’s chillers by 13.6%, leading to an overall plant efficiency improvement of 9.0%, compared with the same period in 2022.

Tabreed’s CEO, Khalid Al Marzooqi, said this development is testament to the company’s tireless pursuit of energy efficiency at every level of its operations, adding that “as a sustainable cooling champion focused on innovation, we are always looking for ways to accelerate the energy transition and provide more efficient services that benefit our customers, our stakeholders and the communities in which Tabreed operates.

“This successful pilot project proves the power of international partnership and technological collaboration, and we look forward to working with HTMS to further the application of their technology to advance sustainable cooling solutions that benefit communities and industries across the world.

“In real terms, what we are looking at here is a potentially seismic improvement in energy efficiency that could radically change this industry. That Tabreed is spearheading such developments should not be a surprise, and I am proud to be leading such a progressive and impactful company that’s completely aligned with the UAE’s inspirational Net-Zero strategy.”

How Maxwell Works in a Chilled Water System

Maxwell’s nanotechnology increases the thermal capacity of water, the base fluid for commercial and industrial chilled water systems. When added to a chilled water loop at a 2% concentration of nano materials, Maxwell increases the system’s cooling capacity by up to 15%. This increased cooling capacity allows chillers, fan units, pumps and other equipment to operate more efficiently, reducing electrical energy consumption and carbon emissions. Maxwell is a non-toxic, non-corrosive material and fully recoverable and recyclable.

Next Steps

Following the promising pilot study results, Tabreed and HTMS are in discussions to introduce the Maxwell technology to other district cooling facilities in the company’s portfolio. With cooling accounting for an estimated 70% of energy consumption in the GCC, and global demand expected to triple by 2050, this technology could potentially play a critical role in reducing the environmental impact of an industry already widely viewed as an essential contributor to sustainability, with district cooling being up to 50% more energy efficient than conventional cooling methods.

Commenting on the successful pilot project, Thomas Grizzetti, CEO of HTMS, said: “Thanks to the ease of installation, and use in both new and existing HVAC systems, Maxwell can have a material impact on energy usage and the carbon footprint of a broad range of industries and sectors globally. Maxwell is a significant step forward for businesses wishing to drive down energy use, increase system capacity and meet regulated energy efficiency targets increasingly promulgated by governments globally. We believe Tabreed is an ideal strategic partner for HTMS to help achieve widespread adoption of this unique technology.

‑ Reproduced from original source

Same temperature, less energy: What HT Materials Science plans to do after closing $15m funding round

THE CURRENCY | Tom Lyons, Chief Executive | March 24, 2023

The fluids traditionally used in heating and cooling are notoriously energy-inefficient, yet there has been no progress for decades in this area. With an easy-to-use product, HT Materials Science has caught the eye of high-profile global investors.

Tom Grizzetti was looking for his next investment six years ago. The search took him to the University of Salento in the historic city of Lecce in Italy, known as the Florence of the South. Grizzetti and his business partner, Irishman Ed Coleman, were looking to meet Professor Arturo de Risi and his team of materials science experts that were working on a product that the two veteran investors believed could change the world.

That revolution was not expected to happen in a dramatic or public way but out of sight in the vast heating, ventilation and air conditioning systems that keep offices and apartment blocks cool and are essential to manufacturing, data centres and all the other things that have become part of our existence.

“We were looking for additives and the effect they could have on energy efficiency,” Grizzetti explained on a video call from London after closing a $15 million Series A round for his business HT Materials Science.

It was an area the finance veteran didn’t know much about until about a decade ago when he and Coleman started to make a few small investments in the sector, prompted by an interest in refrigerants and their negative impact on the environment.

But now Grizzetti and Coleman were really excited about the potential of what de Risi and his team were working on as they delved deeper and got to know the Italian scientists. Over thirty-plus years, de Risi had his name on 11 patents in the thermal energy sector and was Professor of Engineering for Innovation at the University of Salento.

By January 2018, Grizzetti, Coleman and de Risi had founded a new business called HT Materials Science based in Dublin, Lecce and New York. Grizzetti was chief executive, with de Risi as CTO and Coleman as CFO.

The core product they developed is called Maxwell, a ground-breaking sub-micron heat transfer fluid technology that can be “dropped-in” as an additive to new or existing commercial and industrial heating and cooling systems, leading to a 15 per cent reduction in energy consumption.

Maxwell, if it can scale, could have a major impact on lowering energy costs, enhancing equipment performance and reducing carbon emissions. HT Materials Science believes its additive is so effective it can pay back the cost of using it to clients within two to three years. It has a compelling business as well as environmental case.

Grizzetti is telling me about the early days and potential of his business just after raising $15 million from some of the smartest investors in the world including Aramco Ventures, the venture arm of Saudi Aramco, and Barclays, via its Sustainable Impact Capital portfolio.

Italian asset management firm CDP Venture Capital SGR, through its corporate venture capital fund, Corporate Partners I, are also in the round, as is the Progress Tech Transfer fund, a sustainability-focused fund that specialises in working with Italian universities.

HT Materials Science has strong Irish links through a major research affiliation with Trinity College Dublin through AMBER (the Centre for Advanced Materials and BioEngineering Research funded by Science Foundation Ireland). Its executive chair is a Dubliner called Kyran McStay, a co-founder of Irish boutique advisory firm Key Capital, and a former managing director with UBS.

It took Tom Grizzetti a while to become a hands-on executive in a company again. For the previous 16 years, he had been president of his own investment firm called Gotham Industries. “I was doing some investing on behalf of myself and some friends,” Grizzetti said.

Working alongside him, seeking deals and managing investments was his friend Coleman. It was interesting and busy work but it wasn’t the graft of building a business from the ground up.

The last time Grizzetti did that was from 1995 until 2006 when he was chief operations officer and co-founder of alternative investment administrator firm International Fund Services (Ireland).

Grizzetti and his business partners built IFS (Ireland) into a $200 million revenue business. It had 1,200 employees when the business was acquired by State Street Bank in 2002, with a team of 700 in Dublin. Grizzetti stayed with the business until his earn-out finished in 2005, after taking the firm from scratch to global. While working with IFS (Ireland), Grizzetti got to know Coleman who was working with EY as audit partner to the business. He convinced Coleman to join him in the next phase of his career: investing.

They had lots of investments, but how heat transfer fluids were used in cooling and heating systems became a source of fascination. “We became really interested because of the size of the market and the effect on energy efficiency,” Grizzetti said. “We also realised it was an untouched market.”

There had been little innovation in the area of heat transfer fluids despite the surging need for cooling requirements in everything from offices to residential to manufacturing to data centres.

“A really elegant solution”

For decades, cooling and heating systems only used conventional fluids like water and glycol with low thermal conductivity, making them relatively inefficient. Grizzetti and Coleman felt the market was ready to be disrupted. They could see how de Risi and his team could improve the thermal conductivity of fluids to increase the efficiency of energy use, but they knew they needed to build a business to commercialise these ideas.

In January 2018, the inventors and investors teamed up to form a company called HT Materials Science. “We invested money and developed a newer version of heat transfer fluid which ended up becoming our product, Maxwell,” Grizzetti said. Maxwell is made out of sub-micron aluminium oxide particles and is non-corrosive and non-toxic, so it is safe too. “Maxwell is a really elegant solution,” Grizzetti said. “It is simple and not difficult to make or deploy.”

Initially, HT Materials Science was self-funded with between $1 million and $2 million. In summer 2020 it was ready to do a seed round of $2 million led by Progress Tech Transfer with the support of Enterprise Ireland and friends and family investors. “Effectively this allowed us to further develop our technology and do our first deployments in 2021,” Grizzetti said.

From the start, HT Materials Science worked with some of the best companies in the world who, like them, were eager to find new ways to reduce their energy needs. Regeneron Pharmaceuticals, Johnson & Johnson, Swire Pacific, Ericsson and Saudi Aramco deployed its product. Saudi Aramco was so interested in HT Materials Science that in August 2021 its venture arm led a €5 million investment round in the business.

“This became part of our $15 million series A round,” Grizzetti explained. HT Materials Science knew that Maxwell had huge potential. Consultants BCNP estimate that the product is compatible with 13.8 million systems in North America and Europe, an addressable market of over €50 billion a year. “The beauty of our product is that it is an additive so it is easy to retrofit as there is no additional capital expenditure required (to use it in existing systems),” Grizzetti said. “We can retrofit, say, a 500,000 sq ft office space in less than two days… in as little as 16 hours we can do it. In an active system, we can just pump in our additive while we drain fluid.” It was now time to really try and scale.

Kyran McStay became executive chairman of HT Materials Science in January 2022. He had known the firm’s co-founder Coleman for a decade, so he had been following the story, and had been asked to invest passively. “I said to Ed, this is a very interesting technology but I have decided I am only going to invest in businesses from now on where I get involved,” McStay recalled. “We stayed in touch and Ed informed me of progress. Then I got to meet Tom and to really understand the business.” McStay gradually got drawn in, until he accepted the role of chairman accepted the role of chairman.

“What attracted me first and foremost was the quality of the management team,” McStay said. “Ed and Tom have been around the block. They know how to build large organisations.”

“We have a management team capable of scaling this business very quickly, commercialising our technology, building a distribution platform and developing adjacent technologies. I loved the business challenge and found the prospect of working with the team really exciting.”

HT Materials Science’ $15 million series A round was raised in two chunks. The first part was led by Aramco Ventures and the second part by CDP, part of the Italian sovereign wealth fund, as well as Barclays through its Sustainable Impact Capital portfolio, led by Barclays’ Principal Investment team.

When the full round closed recently, this took HT Materials Science total funding to date to $20 million.

Grizzetti said the new funding would allow it to start to build a global sales team and continue to invest in R&D to bring the next version of its product to trial stage at the end of this year. “We are excited to have the backing of Aramco Ventures, Barclays, CDP and PTT. This support from major industry innovators serves as a strong endorsement for our technology and vision,” he said. “Thanks to the ease of installation, and use in both new and existing HVAC (heating, ventilation and air conditioning) systems, we believe that, at scale, Maxwell can have a material impact on energy usage and the carbon footprint of a broad range of industries and sectors.”

HT Materials Science employs 25 people but expects this to go to 35 in the next 12 months or so. In Italy, it has manufacturing capabilities to produce enough product to support sales of up to $20 million. But as Maxwell establishes itself, HT Materials Science intends to migrate to an indirect model using existing sales channels of large energy service companies, facilities managers and original equipment manufacturers to scale. Having its new investors on board will also help. “When you bring in a new investor, one thing is cash but the other is routes to market and commercial validation,” Grizzetti said. “Investors like Aramco Ventures and Barclays give us credibility and help us get to market.”

“Barclays is doing this investment on the bank’s balance sheet as part of its sustainability plan,” he added. “They own a large portfolio of real estate and they can open doors for us.”

Industrial need

Grizzetti said offices and large-scale residential developments were one area they hoped to deploy in, but the other was in industrial applications and data centres. “The industrial area is probably going to be the bigger market for us as they are high energy users who need cooling 24/7,” he said. “I’m sitting here in London so the demand for cooling is low because of the ambient temperature. I think our speciality in the long run will be more on the industrial side but we are focusing on both markets.”

Grizzetti is ambitious for HT Materials Science, and itching to grow. “If we are correct, we will have established a pretty good client base in America, Europe, Asia and GCC (Gulf Cooperation Council countries) in the next few years. We will have completed a series B round of between $25 million and $35 million,” he predicted.

“We will have multiple manufacturing facilities whether in or out of house, which will allow us to become a global business. We have an elegant and simple solution predicated on a known technology that can deliver real energy savings and make a real impact.”

‑ Reproduced from original source

Irish start-up gets $15m backing for fluid that cuts energy bills

IRISH TIMES | Barry O’Halloran | March 24, 2023

Irish start-up HT Materials Science (HTMS) has secured $15 million (€13.8 million) in backing from investors including Aramco Ventures and Barclays to continue developing a product that cuts buildings’ energy bills.

HTMS has developed a fluid, Maxwell, that cuts energy use in commercial buildings’ heating, ventilation and air conditioning systems, helping to tackle key problems in reducing their costs and carbon emissions.

The Irish-headquartered company has just raised $15 million from Saudi Arabia’s Aramco Ventures, Barclays Sustainable Impact Capital, Italy’s CDP Venture Capital and specialist investor, Progress Tech Transfer.

Kyran McStay, HTMS chairman, said the company will use the cash to hire specialised sales staff who will continue to target multinational customers around the globe, and on further research and development.

He said Maxwell – named after pioneering Scottish physicist James Clerk Maxwell – can be added to the water used in cooling systems to improve its efficiency.

However, while water is simple to use, Mr McStay said it’s a “relatively inefficient heat conductor” so HTMS developed Maxwell, a suspension of aluminium particles, which is added to boost its efficiency, thus cutting energy consumption.

The product reduces heating, ventilation and air conditioning carbon emissions and lowers bills by around 15 per cent, he said.

The company has sold the product to Aramco, US pharmaceutical groups, Regeneron and Johnson and Johnson, and real estate giant, Swire Pacific, which uses it in a shopping centre in Hong Kong.

These are trial sales, but have so far proved successful, so should lead to bigger deals. HTMS targeted multinationals as they have a lot of buildings, often with complex heating and cooling systems.

Maxwell’s key attraction is that it eliminates the need to replace these systems while making them more efficient.

Mr McStay said that this is a key problem in tackling buildings’ greenhouse gas emissions. Businesses often cannot afford to replace expensive heating, ventilation and air conditioning systems, leaving little scope to reduce this equipment’s energy use.

One challenge is overcoming companies’ concerns about the possible risk involved in doing something new with existing, expensive equipment.

“You’re talking to engineers and asking them to put something other than water into their cooling systems,” said Mr McStay.

This is why HTMS focuses on sales staff, as they themselves need specialised knowledge to address potential buyers’ doubts.

It is also reason for the product’s name. Mr McStay said “every engineer knows Maxwell’s equation”, which deals with heat transfer.

HTMS employs 25 people, some in Italy, where the product is made and where it was originally developed, in Salento University.

The company chose the Republic as its headquarters as chief executive, Thomas Grizzetti, whose background is finance, was working here when research led him to the idea.

HTMS has a research partnership with Trinity College Dublin and has received backing from Enterprise Ireland.

Mr McStay said the company found it easy to find the expertise it needed here, while the Republic provides a “natural springboard” for selling to multinationals.

‑ Reproduced from original source

Energy giant Saudi Aramco leads €5m investment in Irish company

HT Materials Science has developed technology used in heating and cooling systems.

IRISH TIMES | Charlie Taylor | August 11, 2021

HT Materials Science, an Irish developer of technology used in heating and cooling systems, has raised €5 million in investment in a Series A funding round led by energy giant Saudi Aramco.

The Dublin-based company, which was founded in 2018 by Tom Grizzetti, Arturo de Risi and Rudy Holesek, produces heat-transfer fluid additives which, when added to existing water and glycol heating and cooling systems, yield improvements in energy use and system capacity.

HTMS claims its flagship Maxwell 2020 fluid products can help businesses seeking to drive down energy costs, increase system capacity and meet climate change and emissions targets.

The global heat-transfer fluid market in which it is operating is worth an estimated €100 billion.

The financing is being used to fund HTMS’s growing list of commercial validation projects; further develop its technology and range of products; scale its manufacturing capability; and invest in sales and distribution networks.

Saudi Aramco Energy Ventures co-led the investment in partnership with Progress Tech Transfer, a Luxembourg-based fund specialising in sustainable technologies.

Saudi Aramco is the world’s largest oil company. It announced a nearly fourfold rise in second-quarter net profit on Sunday last, bolstered by higher oil prices and a recovery in oil demand. The state oil producer reported net profits of 95.47 billion riyals (€21.7bn) for the quarter ending June 30th, up from 24.62 billion riyals a year earlier.

“We’re excited to have partners on board that provide us not only with capital, but with access to commercial partners through their broad strategic experience in the markets we serve,” said Mr Grizzetti, HTMS’s chief executive.

‑ Reproduced from original source